New for 2024, the Street Killer shirt features super soft cotton and lets you rock out with a sick R34 GT-R. Show off your JDM pride!

Available in sizes from small to 2XL.

New for 2024, the Street Killer shirt features super soft cotton and lets you rock out with a sick R34 GT-R. Show off your JDM pride!

Available in sizes from small to 2XL.

Installing a fuel cell bulkhead in a tight space? These can help make it a little easier to connect your fuel system’s AN fittings if you’re height restricted!

New for our AN Union adapters featuring an NPT Port, you can now get this product in 45 and 90 degree angles to accommodate additional plumbing system solutions.

We have revised our banjo bolt inventory to include a greater variety of sizes to accommodate additional plumbing solutions for our customers. Now included in our specifications are head diameter, overall and underhead lengths, and metric thread. Expanded standard thread banjo bolts will be made available soon for purchase as well.

G-thread (from Gas or Gewinde) is a 55 degree parallel pipe thread. These can have male or female thread and o-rings can be used for low pressure lines under static load.

G-threads are NOT compatible with NPS, nor are they compatible with any tapered thread such as NPT or BSPT. The angle, shape, and thread-pitch of the threads are different, and attempting to use or force the use of these threads can damage the fitting, requiring replacement.

According to the current G-thread standard, the specs are identical to BSPP (British Standard Pipe Parallel) and can be used interchangeably. If, for example, you have a G1/8 fitting, you can use a 1/8″ BSPP fitting in its place.

You may encounter G-thread fittings or threaded holes on some European vehicles.

BSPP to AN adapter fittings are available on our website under the BSP Adapters product category.

Dry break quick disconnect and fittings are vital components in motorsport applications. They allow for quick and easy fuel and oil changes during pit stops, reducing the amount of time spent in the pit lane and increasing the team’s chances of winning. But what exactly are they, and how do they work?

Dry break quick disconnect and fittings are a type of coupling system that allows for fast and easy connection and disconnection of fuel and oil lines. They are designed to eliminate spills and drips when disconnecting lines, which can be dangerous in a high-performance motorsport environment. They are typically made of lightweight and durable materials such as aluminum or stainless steel, and come in a variety of sizes and configurations to suit different motorsport applications.

The dry break quick disconnect and fittings system consists of two parts: the male and female halves. The male half is typically attached to the fuel or oil line, while the female half is attached to the fuel or oil tank. The two halves are designed to connect and disconnect quickly and easily, with no need for tools or special equipment.

The dry break quick disconnect and fittings system is ideal for motorsport applications where fast and efficient pit stops are essential. For example, in endurance races, where every second counts, a quick fuel or oil change can mean the difference between winning and losing. The system is also popular in drag racing, where speed and performance are crucial.

One of the main advantages of dry break quick disconnect and fittings is their ability to prevent spills and drips. This is particularly important in a motorsport environment, where a small fuel or oil spill can be dangerous. The system is designed to be completely leak-proof, meaning that fuel and oil will not escape when disconnecting the lines.

Another advantage of the system is its ease of use. With no need for tools or special equipment, the system can be quickly and easily connected and disconnected by pit crew members. This means that pit stops can be carried out quickly and efficiently, reducing the amount of time spent in the pit lane.

In conclusion, dry break quick disconnect and fittings are an essential component in motorsport applications. They offer a fast and efficient way to change fuel and oil lines during pit stops, while also preventing spills and drips. They are easy to use and can be quickly and easily connected and disconnected by pit crew members, making them an essential tool for any motorsport team looking to gain a competitive edge.

In motorsports, having a reliable fuel system is crucial for performance and safety. One of the most important components in the fuel system is the fuel filter. A fuel filter’s main function is to remove any impurities, such as dirt, rust, and debris, from the fuel before it enters the engine. This helps to protect the engine from damage and ensures that the engine is running on clean fuel.

Motorsport fuel filters are designed to handle the high-performance demands and harsh conditions of motorsports. They are typically made from high-quality materials, such as aluminum or stainless steel, which can withstand high temperatures, pressures, and vibrations. Some of the fuel filters are designed to be reusable, while others are designed to be disposable.

There are a few different types of motorsport fuel filters available, each with their own set of advantages and disadvantages. The most common types of motorsport fuel filters are paper element filters, reusable element filters, and foam element filters.

Paper element filters are the most common type of fuel filter and are typically the most affordable. They are made from a pleated paper material that is designed to trap impurities and debris. They are disposable, which means they need to be replaced when they become clogged.

Reusable element filters, also known as washable filters, are another popular choice for motorsports. They are made from a metal mesh or wire material that can be cleaned and reused multiple times. They are more expensive than paper element filters, but they have a longer lifespan and can save money in the long run.

Foam element filters are similar to reusable element filters but are made from a foam material. They are also washable and reusable, and can filter out smaller particles than paper or metal element filters. However, foam element filters can absorb fuel and can become heavy, so they need to be checked regularly and cleaned when necessary.

When choosing a fuel filter for motorsports, it’s important to consider the type of engine, the type of fuel, and the conditions in which the vehicle will be used. For high-performance engines, a reusable or foam element filter may be a better choice as they can handle higher flow rates and filter out smaller particles. For vehicles that will be used in harsh conditions, a filter made from aluminum or stainless steel may be a better choice as they can withstand high temperatures, pressures, and vibrations.

In conclusion, motorsport fuel filters are an essential component of a high-performance fuel system. They remove impurities and debris from the fuel, protecting the engine from damage and ensuring that the engine is running on clean fuel. There are a few different types of motorsport fuel filters available, each with their own set of advantages and disadvantages, so it’s important to choose the right one for your specific application.

NPT fittings, also known as National Pipe Thread fittings, are a type of fitting commonly used in industrial, automotive, and plumbing applications. They are designed to provide a secure, leak-free connection for fluid and gas systems, and are known for their durability and versatility.

NPT fittings are designed to connect to pipes or hoses that have NPT threads, which are a specific type of thread that is tapered and designed to create a tight seal when connected. NPT fittings come in a variety of sizes, styles, and materials, which allows them to be used in a wide range of applications.

One of the main advantages of NPT fittings is their ability to handle high pressures and temperatures. They are typically made from brass, stainless steel, or carbon steel, which are strong and durable materials that can withstand the high pressures and temperatures found in industrial, automotive, and plumbing applications. Additionally, NPT fittings are designed to be reusable, which means they can be disconnected and reconnected multiple times without losing their seal.

Another advantage of NPT fittings is their versatility. They come in a variety of sizes and styles, which allows them to be used in a wide range of applications. For example, they are commonly used in compressed air systems, fuel systems, water systems, and oil systems. They can also be used to connect pipes, hoses, valves, and other components together.

When it comes to selecting NPT fittings, the first thing to consider is the size of the fitting. NPT fittings are available in a range of sizes, from 1/8″ to 2″, with 1/8″ being the smallest and 2″ being the largest. The size of the fitting you choose will depend on the size of the pipe or hose you are using, as well as the pressure and flow rate of the fluid you are working with.

Another important factor to consider when selecting NPT fittings is the type of fitting. There are a few different types of NPT fittings available, including straight, elbow, and tee fittings. Straight fittings are used to connect two pipes or hoses together, while elbow fittings are used to change the direction of a pipe or hose. Tee fittings are used to split a line into two or more lines.

Lastly, it’s important to consider the material of the fitting. NPT fittings are commonly made from brass, stainless steel, or carbon steel. Brass fittings are corrosion-resistant and suitable for most applications. Stainless steel fittings are stronger and more durable, and are typically used in high-pressure and high-temperature applications. Carbon steel fittings are strong and durable and typically used in heavy-duty industrial applications.

In conclusion, NPT fittings are a popular choice for industrial, automotive, and plumbing applications for their strength, durability, and versatility. They are designed to handle high pressures and temperatures, and come in a variety of sizes, styles, and materials. When selecting NPT fittings, it is important to consider the size, type, and material of the fitting to ensure that it is suitable for your application.

AN fittings, also known as Army-Navy fittings, are a type of fitting used in high-performance automotive and racing applications. They are designed to provide a secure, leak-free connection for fuel, oil, and other fluid systems, and are popular among car enthusiasts for their strength, durability, and versatility.

One of the main advantages of AN fittings is their ability to handle high pressures and temperatures. They are typically made from aluminum or steel, which are strong and lightweight materials that can withstand the high pressures and temperatures found in high-performance engines. Additionally, AN fittings are designed to be reusable, which means they can be disconnected and reconnected multiple times without losing their seal.

Another advantage of AN fittings is their versatility. They come in a variety of sizes and styles, which allows them to be used in a wide range of applications. For example, they are commonly used in fuel systems, oil systems, brake systems, and intercooler systems. They can also be used to connect hoses, lines, and other components together.

When it comes to selecting AN fittings, the first thing to consider is the size of the fitting. AN fittings are available in a range of sizes, from -4 to -20, with -4 being the smallest and -20 being the largest. The size of the fitting you choose will depend on the size of the hose or line you are using, as well as the pressure and flow rate of the fluid you are working with.

Another important factor to consider when selecting AN fittings is the type of fitting. There are a few different types of AN fittings available, including straight, elbow, and tee fittings. Straight fittings are used to connect two hoses or lines together, while elbow fittings are used to change the direction of a hose or line. Tee fittings are used to split a line into two or more lines.

Lastly, it’s important to consider the material of the fitting. AN fittings are commonly made from aluminum or steel. Aluminum fittings are lightweight, corrosion-resistant, and suitable for most applications. Steel fittings are stronger and more durable, and are typically used in high-pressure and high-temperature applications.

In conclusion, AN fittings are a popular choice among car enthusiasts and racers for their strength, durability, and versatility. They are designed to handle high pressures and temperatures, and come in a variety of sizes, styles, and materials. When selecting AN fittings, it is important to consider the size, type, and material of the fitting to ensure that it is suitable for your application.

Oil cooler hoses are an essential component of any engine’s lubrication system. They are responsible for transporting hot oil from the engine to the oil cooler, where it is cooled down before being circulated back into the engine. This process helps to keep the engine running at optimal temperatures, which can help to improve performance and extend the life of the engine.

Oil cooler hoses are typically made from rubber or silicone, and they come in a variety of sizes and shapes to fit different engine configurations. They are designed to withstand the high temperatures and pressures of an engine’s lubrication system, and are typically reinforced with fabric or wire to provide additional strength and durability.

There are a few things to consider when choosing oil cooler hoses for your engine. The first is the type of engine you have. Some engines, such as high-performance racing engines, may require hoses that can withstand higher temperatures and pressures than a standard passenger car engine. This is because high-performance engines generate more heat and put more stress on the lubrication system. For high-performance or motorsport applications, FLF recommends the use of a nylon-braided rubber hose to handle the temperatures, pressures, and chemical resistance necessary for oil cooler systems.

It’s also important to consider the routing of the hose, as oil cooler hoses that are routed through tight spaces or tight bends may be more prone to failure. Make sure to choose hoses that are flexible and have a large enough minimum bend radius for your application.

In conclusion, oil cooler hoses play a vital role in keeping your engine running at optimal temperatures. When choosing hoses for your engine, it’s important to consider the type of engine, the type of oil, routing, and the type of connector. With the right oil cooler hoses, your engine will run smoothly, efficiently, and last longer.

E85 fuel, also known as flex fuel, is a blend of 85% ethanol and 15% gasoline. It has become increasingly popular in recent years as a way to reduce dependence on fossil fuels and lower emissions. However, it also poses some unique challenges when it comes to fuel delivery systems.

One of the biggest issues with E85 is its tendency to cause hose failure. This is because E85 is more aggressive than gasoline, and can cause the hoses in a fuel system to degrade over time. The hoses can become brittle and crack, which can lead to leaks and even engine failure.

To combat this problem, many automakers and aftermarket companies have started using PTFE (polytetrafluoroethylene) hoses in their fuel systems. PTFE is a synthetic fluoropolymer of tetrafluoroethylene, which is resistant to chemical attack, high temperatures, and pressure. PTFE hoses are much more resistant to the corrosive effects of E85 than traditional rubber hoses, and are less likely to crack or fail.

PTFE hoses are also more flexible than traditional rubber hoses, which makes them ideal for tight spaces and tight bends. They are also much more resistant to heat, which is important in high-performance engines.

However, PTFE hoses are not without their own set of challenges. They are slightly more expensive than traditional rubber hoses, which can make them cost-prohibitive for some applications. They also have a much higher minimum bend radius, which can make them difficult to route in tight spaces.

In conclusion, E85 fuel is a great alternative to gasoline, but it can be challenging to use in fuel systems. PTFE hoses offer a solution to this problem, but they are also not without their own set of challenges. It is important to weigh the pros and cons of both options when deciding on a fuel delivery system for an E85-compatible engine. PTFE hoses are a great option for those who want the added durability and resistance to E85, but they come at a higher cost.

A catch can is a great way to filter excess oil vapor and other contaminants from your oil and prevent them from entering your intake system, it can improve engine performance and help keep your engine’s valves clean and free from deposits. However, among the enthusiast community I have seen these installed improperly, and this can lead to poor performance or other problems. I’ve spent significant time, research, and experimenting with different catch can setups to determine what performs best for a naturally aspirated or forced induction engine.

First let’s look at what your factory or OEM setup might look like. You probably have one or more PCV valves on your valve cover and one or more ports on your block. When your intake manifold is in vacuum (throttle closed or partially closed) the valve opens, evacuating the crankcase of vapors. The PCV valve is also metered, meaning it’s designed to only allow a certain amount of air to flow through it. An unmetered valve, like a check valve, could cause a high idle or excessive crankcase vacuum.

High idle is wasting fuel and adding unnecessary NVH and can cause overheating when stopped. Excessive crankcase vacuum is also bad, remember that your engine has rubber seals that are designed to keep oil from leaking out, not from air leaking in. If your setup is causing high crankcase vacuum, you can actually force air to come in around the seals, possibly causing them to fail and start leaking oil later on. The PCV valve helps regulate the pressure between the intake manifold and the crankcase to keep things in check.

You should also have a connection between your valve cover and intake pipe, either leading up to your throttle body or up to your turbo/supercharger. This serves two functions, one is to serve as a source of filtered air into the engine ( this is why it’s called a breather) and to also serve as a vent for excess crankcase vapors when the PCV valve is closed, such as under boost or full-throttle acceleration.

This is fine for stock engines or engines with slight modification, but it’s less than ideal for performance or boosted engines. Excess oil vapor is allowed into the intake manifold and combustion chamber to be burned, which is problematic because oil has a much lower octane rating than even Regular gasoline and the PCV valve can leak under boost, further pressurizing the crankcase with boost pressure.

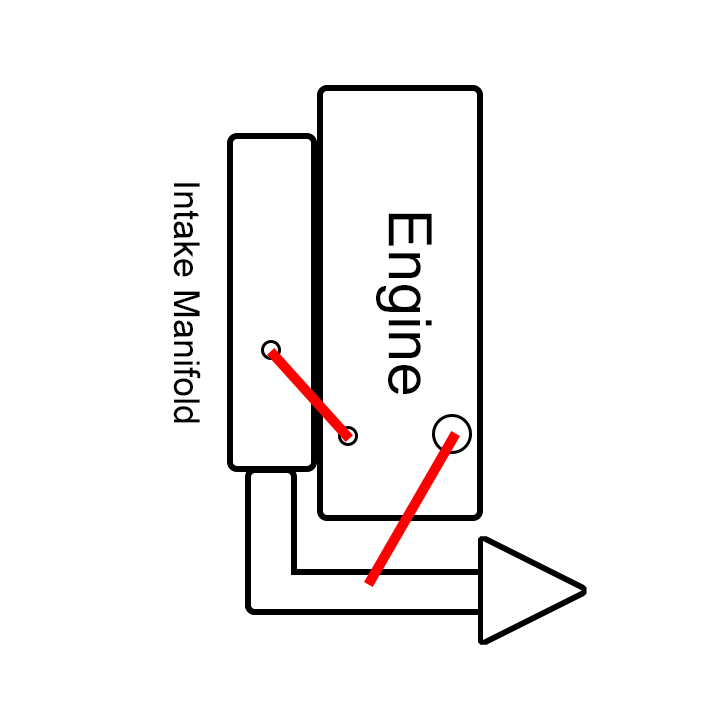

Next let’s look at a simple catch can setup:

In this basic catch can setup, the catch can sits between the PCV valve(s) and the intake manifold port. This captures the oil vapor that normally would pass directly into the intake manifold under vacuum, helping to keep your valves clean. However, the breather port is still connected directly to the intake, and some oil vapor may still pass through into the manifold.

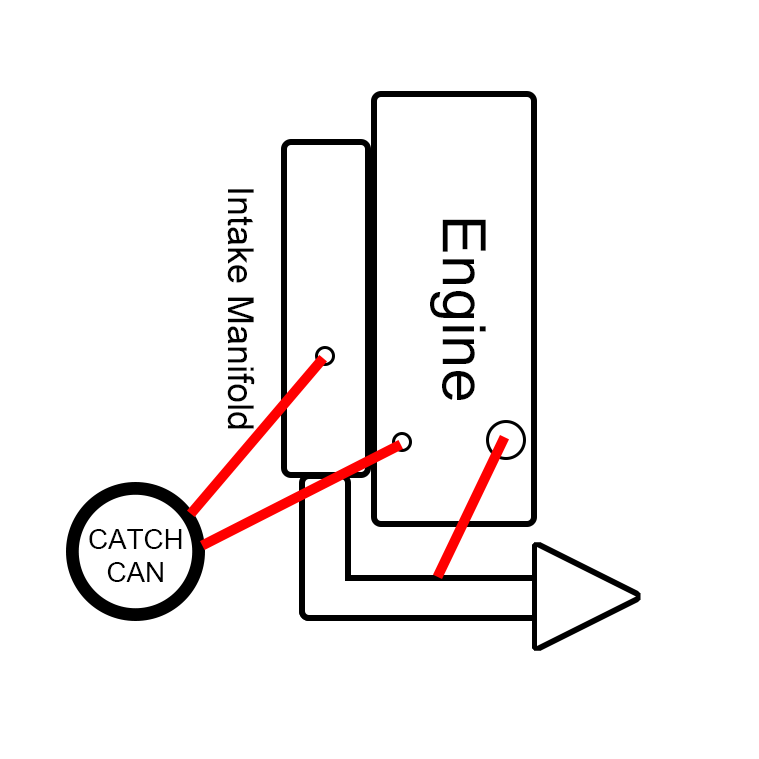

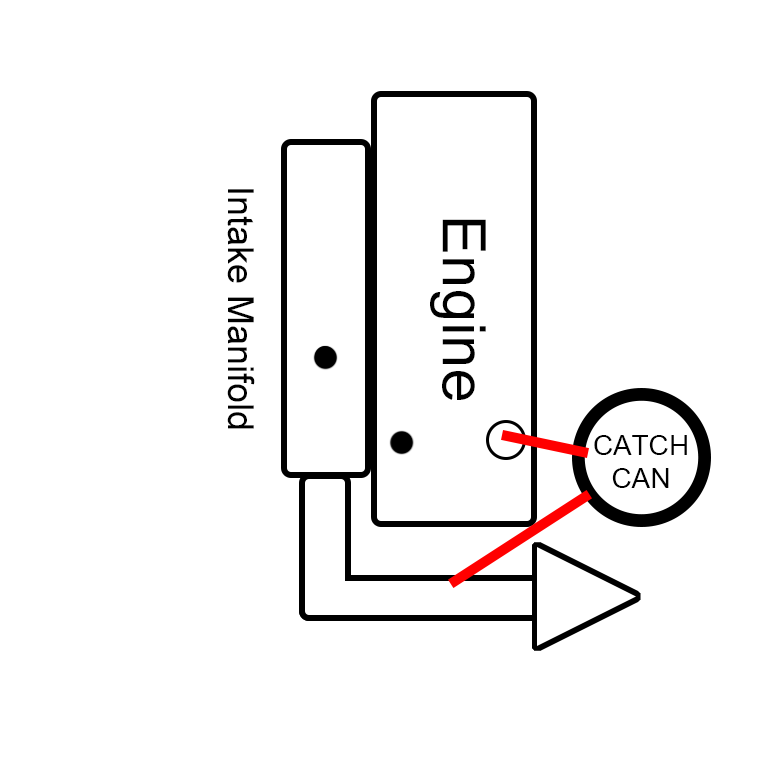

Let’s look at another setup:

In this setup, the intake manifold port is blocked off or capped and the PCV and breather ports are connected to a catch can, then connected to the intake tube. This is pretty simple and will capture some vapor gases, but there isn’t sufficient pressure differential between the crankcase and the intake tube to evacuate the crankcase. The result of this can be a buildup of pressure inside the engine, causing oil to leak past the crank and cam seals and possibly cause oil to back up in the turbo and seep past the seals.

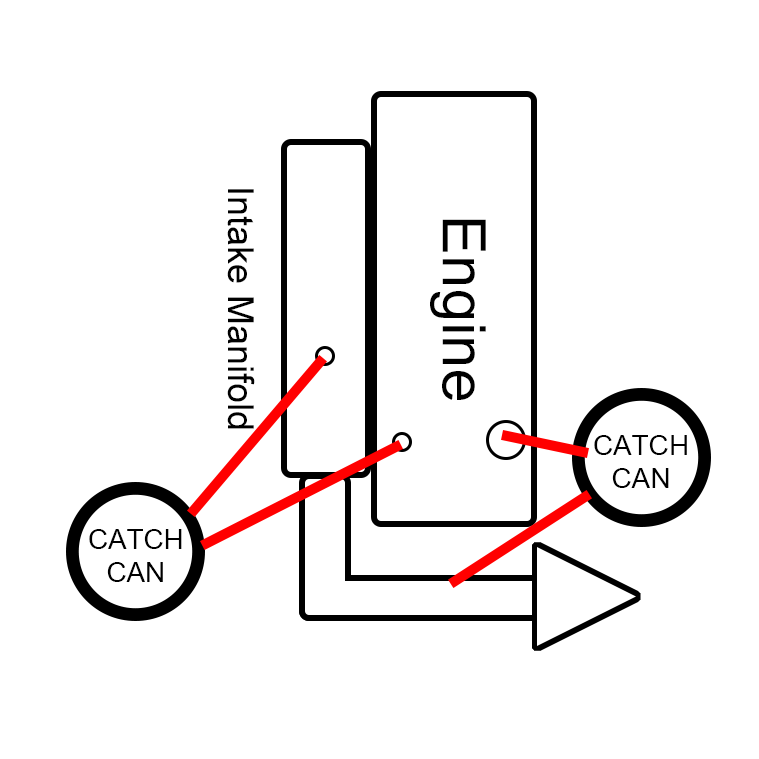

Let’s look at the system that we recommend the most:

This is what we recommend, the dual catch can system. We believe that this is the best-case scenario that enables the PCV valve to do it’s job in regulating airflow, the PCV-side catch can to capture oil being evacuated by the manifold vacuum, and allows the breather side to work properly to ensure proper airflow into and out of the crankcase. You may connect the breather-side catch can either to the intake tube or vent-to-atmosphere if regulations allow.

The downsides to this setup are that space may be a concern in tight engine bays as having two catch cans and the plumbing running around the engine bay might make fitting them a concern, but we believe this is well worth the trouble to ensure peak performance and reliability.